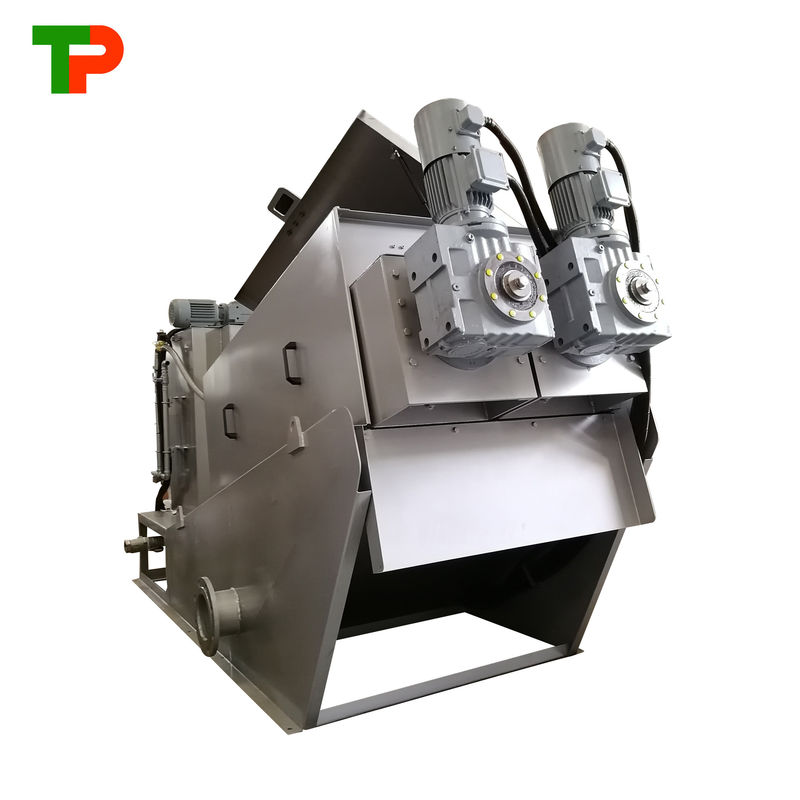

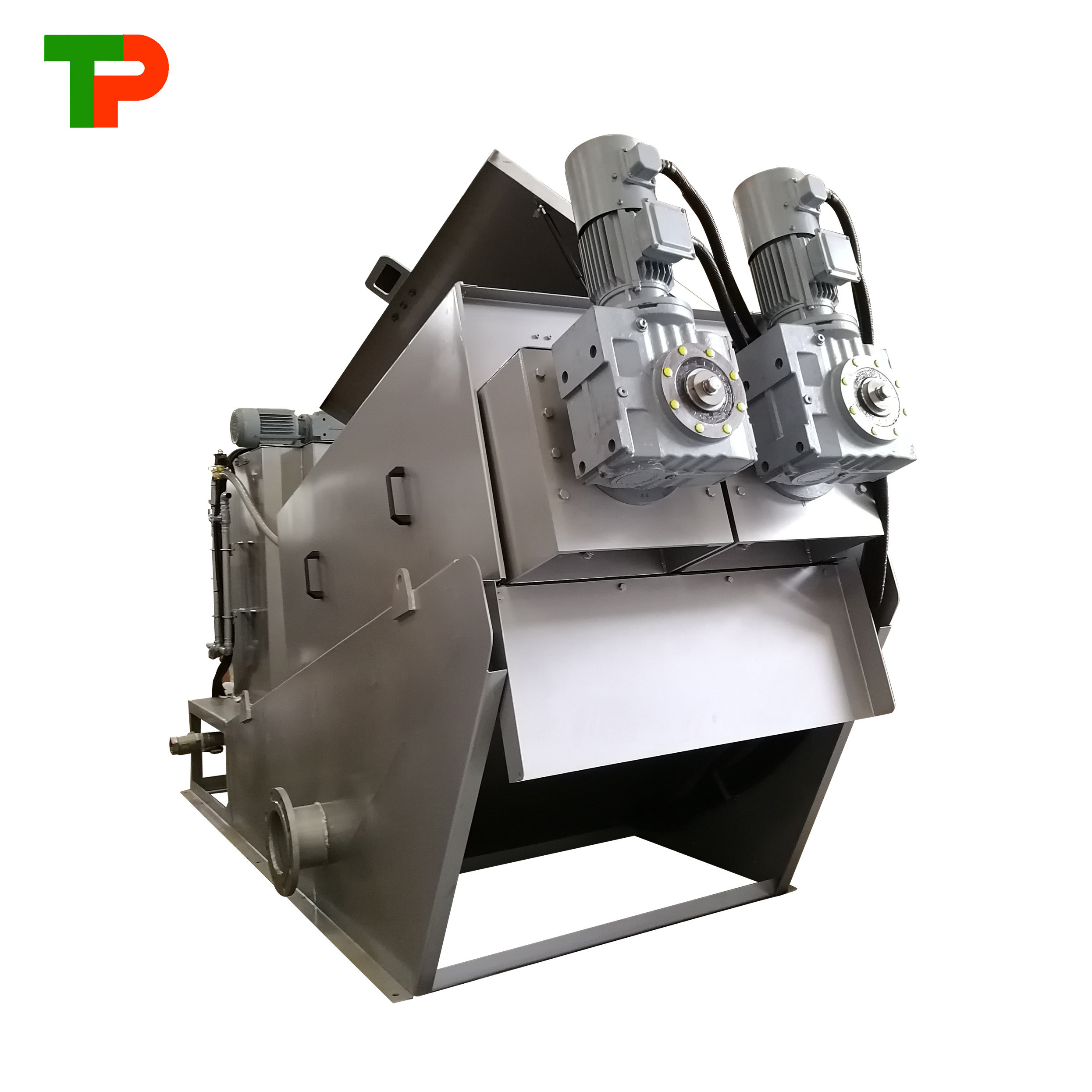

Multi-layer sludge dewatering machine for various chemical wastewater treatment

Product introduction

Volute Sludge Dewatering Machine( Hereinafter referred as TPDL ) belongs to the screw press, it's clog-free and can reduce the sedimentation tank and sludge thickening tank, saving the cost of sewage plant construction. TPDL using screw and the moving rings to clean itself as clog-free structure, and controlled by the PLC automatically, it's a new technology that can replace the traditional filter press like belt press and frame press, the screw speed is very low, so it cost low power and water consumption in contrast to the centrifuge, it is a cutting edge sludge dewatering machine.

Usage

• Municipal water and wastewater treatment plants • Agricultural/fishery community wastewater treatment plants

• Industrial waste treatment plants

• Food/beverage production plants

• Dairy farming/Meat processing plants

• Chemicals manufacturing plants

• Machinery manufacturing/Metal processing plants

• Laundry wastewater

Main Features

1, Clog-free It can handle oily sludge without any trouble while separating the water from the sludge easily.

2,Fully Automatic Control Combining with the auto control system, the machine runs very safely and simply and can be programmed according to the requirement of the users.

3,No secondary pollution No vibration and noise is very small.

4,Promote the phosphorus removal capability Dewatering sludge under aerobic conditions, it does not occur phosphorus release, so as to enhance phosphorus removal function of the whole sewage treatment system.

5,Suitab for Oily Sludge

6,Ave Running Cost It saves energy and water and has very minimal noise because of low running speed (2-4 r/min).

7,Lightweight and durable

8,Decrease Project Investment

Brief Introduction

Our strength: Mechanical part

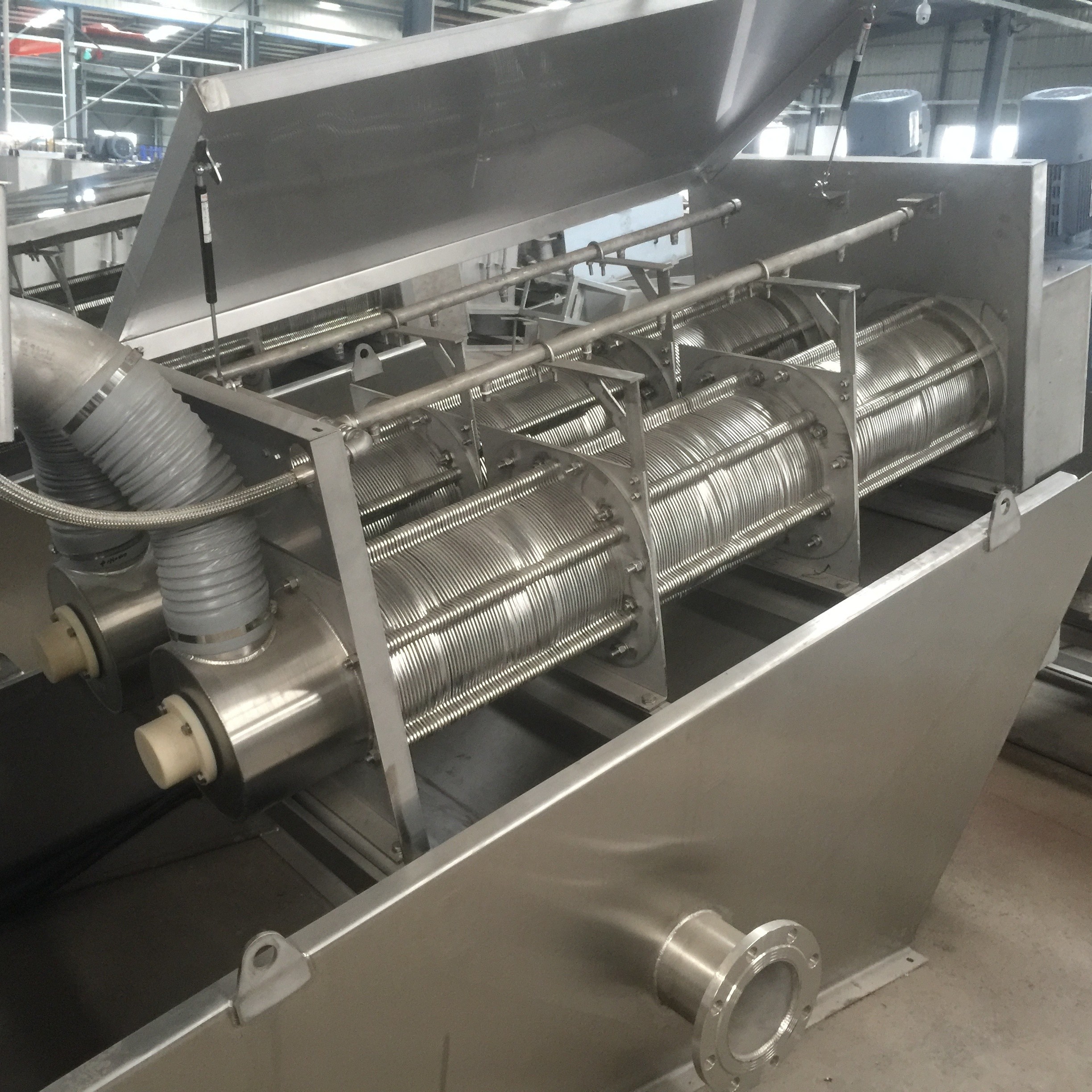

Screw shaft: we use SS 304/316 as material, and adopt Resurfacing Welding technology and wear-resistant metal powder spraying technology which improve the service-life of screw shaft greatly.

Moving and fixed rings: we adopt laser cutting technology.

Gaskets: we use finishing gaskets, not stamping gaskets. All the materials we use are certificated.

Electrical part

Reducer: we cooperate with International and Chinese first class brands, like SEW, Guomao, NORD, Wuma, etc., and adopting inverter to adjust its rotation rate to treat different sludge more efficiently.

Control system: we can provide both button type and PLC with touch screen. The brands of electric components are Schneider, Siemens, Chint, Delix, etc. to ensure the precision of control system.

Auxiliary equipment

We can supply the whole set of sludge dewatering equipment, like dosing device, screw converyor, screw press, etc., providing you a full range of professional service of sludge dewatering!

After-sale service

We give some free spare pasts with every factory machine, and supply all spare parts of our machines for their whole service-life. Customer of dozen years ago can get spare parts from our factory.

We can provide installation and debugging service on site depending on the customers’ requirements.

Videoconferencing and To-site. When you have a problem, we are 24 hours online for you. When the trouble cannot be shot online, we will send engineer to your plant from our nearest overseas office.

Model and Specification:

| Model | DS (KG/H) | Power (kw) |

| TPDL 131 | 5-10 | 0.36 |

| TPDL132 | 10-20 | 0.54 |

| TPDL 251 | 15-30 | 0.92 |

| TPDL 252 | 30-60 | 1.47 |

| TPDL 301 | 30-60 | 1.3 |

| TPDL 302 | 60-120 | 2.05 |

| TPDL 303 | 90-180 | 3 |

| TPDL 351 | 50-100 | 1.85 |

| TPDL 352 | 100-200 | 2.95 |

| TPDL 353 | 150-300 | 4.4 |

| TPDL 401 | 80-160 | 3 |

| TPDL 402 | 160-320 | 4.5 |

| TPDL 403 | 240-480 | 7.5 |

| TPDL 404 | 320-640 | 9 |

*Above parameters only for reference, customized available for detailed requirements

Packaging and Shipping:

FAQ:

FAQ:

Q What is the material?

A It's stainless steel, can be steel 304, 304L, 316, 316L or other grade.

Q: How to choose the most suitable model?

A: Advise us the sludge source, treating capacity, solid content rate, then we could choose the suitable model for you. Please put forward if you have special requirements.

Q: Are you trading company or manufacture?

A: We are manufacture .

Q: Do you offer after-sales service?

A: Yes. Engineers available.

Q: What kind of transportation do you offer?

A: Customers decide freight mode, Air, Land & Sea

Any plans & inquiry, Please contact Maksim Zhou

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!